Encapsulation Technology.

Coolon’s signature technology for protecting and enhancing Architectural luminaries.

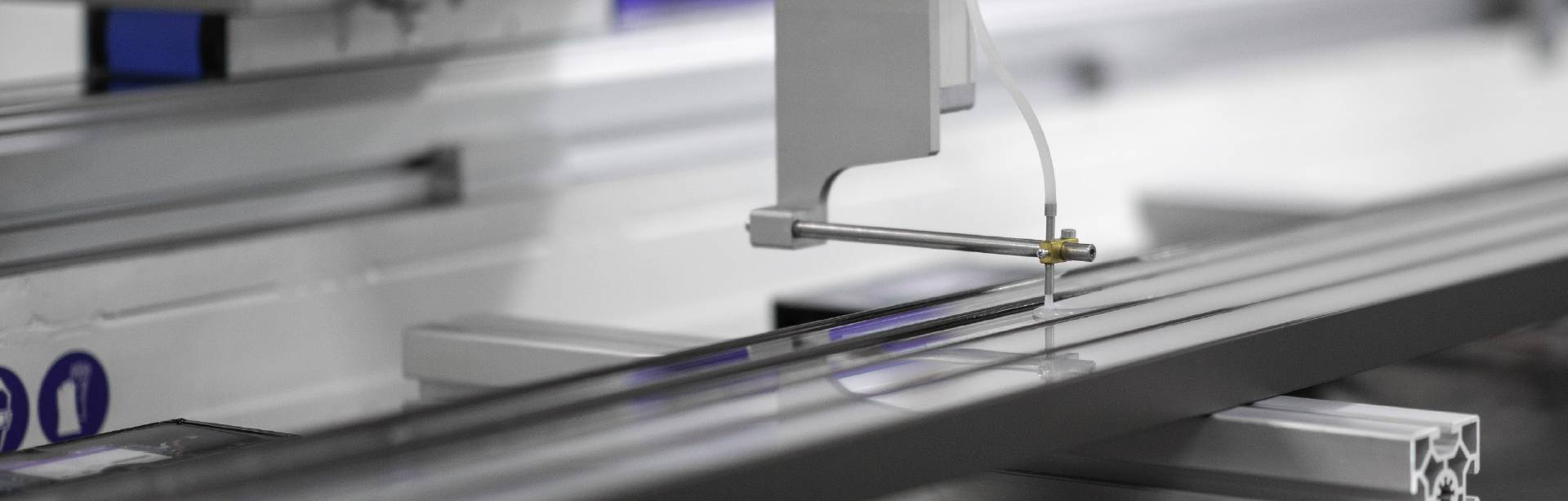

The encapsulation process involves a custom-designed 11-metre-long line from the Demak group, equipped with two three-metre-long pouring beds that each incorporate an oven. Each project is unique, and the process is set up and controlled by a skilled operator that manages the encapsulation process.

As one of the final manufacturing steps for each made-to-order Coolon luminaire that requires it, each piece is arranged on the beds ready for encapsulation. A thermosetting polyurethane resin is precisely flowed into each extrusion and then allowed to solidify, first undergoing a polymerisation process in the low-temperature oven and then curing at room temperature.

The materials are loaded automatically from storage tanks through volumetric piston pumps that are under continuous vacuum. This controlled dispensing system ensures that small air bubbles are removed and avoids additional risks seen in manual systems, including contact with contaminants. Our advanced low viscosity resins and precise curing processes ensure excellent adhesion to enclosure surfaces without shrinkage or volume reduction.

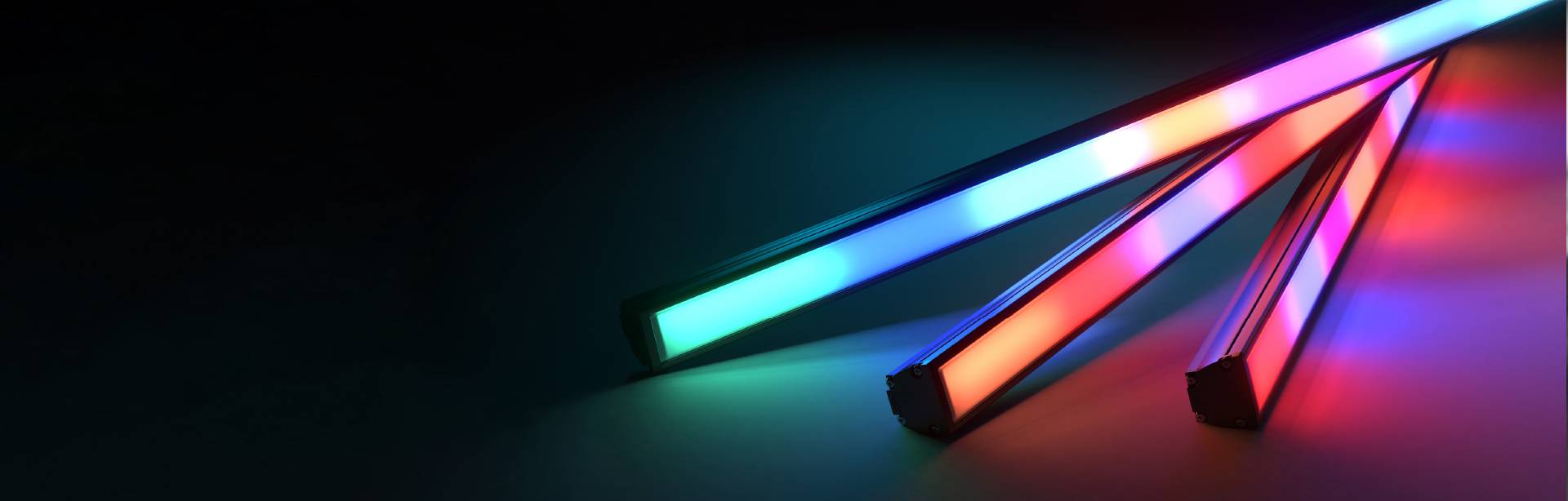

This clean and precise encapsulation method guarantees reliability, durability and quality, and provides multiple desirable physical characteristics and technical advantages.

A softer resin formula is placed within the luminaire profile, providing flexibility during normal operating temperature fluctuations. The luminaire is then finished with a hard, translucent layer that acts as a diffuser, providing a perfectly uniform illumination without any visible dots – perfect for direct view applications. Luminaires can also be installed close to vertical mounting surfaces with no risk of unsightly scalloping effects.

Each IP product with optics contains a specially designed and moulded potting envelope that sits over each optic. This ensures that the polyurethane resin doesn’t come into contact with the optics, which would fill the precise ridges and impede their effect. A clear resin is used over the potting envelope to ensure optical clarity, with the option of embedded micro louvres for glare control on some of our products.

Each seamless piece of acrylic in our Interra range has a precisely routed rebate to house its populated multilayer circuit board. To complete the luminaire, the acrylic piece is fully sealed with our polyurethane resin from the underside. The Interra segments can then be installed end-to-end to create a seamless line of gorgeous inground illumination.

We go to painstaking lengths to ensure our luminaires perform - we don’t take any chances. If water immersion is required - connections are critical.

For this application we offer gel-filled polycarbonate profile LED strip up to 2.5 metres in length. When equipped with two-metre Teflon cables and terminated in a dry location, the strip is suitable for constant water immersion (IP68).

Our reputation as the industry leader of industrial luminaires means we’re no stranger to tough environments. We apply this philosophy and commitment to durability just as stringently to our architectural products. learn more about our architectural testing process.

Protection of electrical components against water and dust.

|

|

|

|

|

|

|

|

|

Emergency Alerts Across Your Site

Emergency Alerts Across Your Site

13 • 02 • 2025

Brilliant Connected Lights serve as a site-wide alert system. In an emergency, the network activates its signal indicators, displaying the colour relevant to the emergency code.

Every Light Can Be an Emergency Light

Every Light Can Be an Emergency Light

11 • 02 • 2025

When it comes to emergency preparedness, lighting plays a crucial role in maintaining visibility, safety, and overall functionality in the event of a power outage.